Solutions > Industrial IoT > Clients Cases-MFG Solutions

Clients Cases-IoT-MFG Application

The IoT-MFG application provides intelligent factory application for factory managers, factory equipment maintenance, and factory quality management.

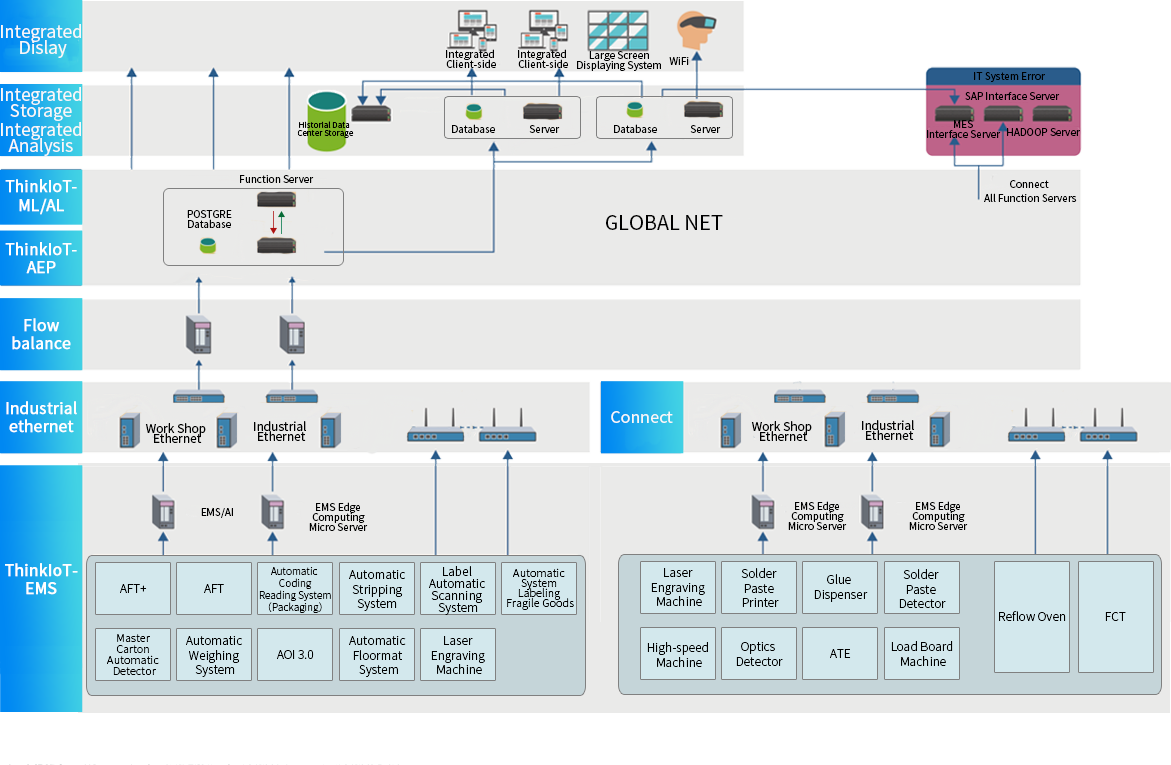

Architecture of IoT-MFG Platform

Device layer:This includes various production machines, lathes, robots, AGVs, warehousing and logistics devices, as well as auxiliary devices such as energy, water, video, environment and security for production.

Communication layer:This achieves the interconnection between devices and the cloud server. The gateway and the device layer are connected via fieldbus, LoRa and other communication modes, and the gateway and the server are connected via Ethernet, WiFi, 4G and other communication modes.

Application layer:Lean production, agile services, data management, big-data analysis.

IoT-MFG Intelligent Factory Application System

IoT-EMS

IoT-EMS

IoT-IFM

IoT-IFM

IoT-EMS is used in the intelligent factory for the data-based interconnection of factory equipment and systems to form the intelligent factory application

Lean production APP

Lean production APP

Agile service APP

Agile service APP

IoT-MFG Features

![]() Fast device connection

Fast device connection

IoT-EMS has more than 150 industrial protocol interfacing capabilities. It can be connected to general and special devices in electronic, machine tool, robot, AGV, textile, mechanical processing and automobile manufacturing industries.

![]()

Fast enhancement and changing

![]()

Fast creation of analysis model

![]()

Fast attempt failure

![]() Fast solution development

Fast solution development

Factory kanban, production line kanban, and device kanban have been quickly formed for applications for different objects of the manufacturing industry, and such solutions as device alarm, report, device OEE, quality kanban, and factory equipment connection kanban have been rapidly developed.

![]()

Fast creation of business value